Curious about what's inside your e-bike or e-scooter battery? It's okay if you haven't thought about it before. Whether you're into DIY projects or just interested in the tech behind your ride, we've got some cool insights to share. And if you're thinking about upgrading your e-bike with our Electric Pedal Power kits, you might find this information particularly interesting.

1. Ebike and Escooter Batteries come in different shapes and sizes

E-bike and e-scooter batteries come in a variety of shapes and sizes, catering to different designs. Examples include rectangular batteries snugly fitting into a scooter deck, externally mounted Hailong batteries popular in DIY circles, and integrated down-tube batteries discreetly concealed within bike frames.

Image 1: A securely placed rectangular battery within an electric scooter's frame.

Image 2: A Hailong-style battery top-mounted on a DIY e-bike.

Image 3: An integrated e-bike battery cleverly hidden within the frame.

2. What's inside an ebike & escooter battery

While the external appearance of an e-bike battery is intriguing, understanding the internal components is crucial for DIY enthusiasts. The majority of commercially available e-bike batteries rely on lithium-ion (Li-ion) technology, specifically 18650 or 21700 cells, each varying in diameter and length. Alternatively, lithium polymer (LiPo) batteries are known for their flat form and great discharge rate but are more commonly used for smartphones, laptops or hobby craft.

Image 4: A glimpse inside a Hailong battery case - individual cells look similar to AA batteries.

3. How are ebike and electric scooter batteries made

Skipping the intricate details of lithium mining and chemical processes leading to battery cell formation, let's explore the assembly of an e-bike battery in a factory.

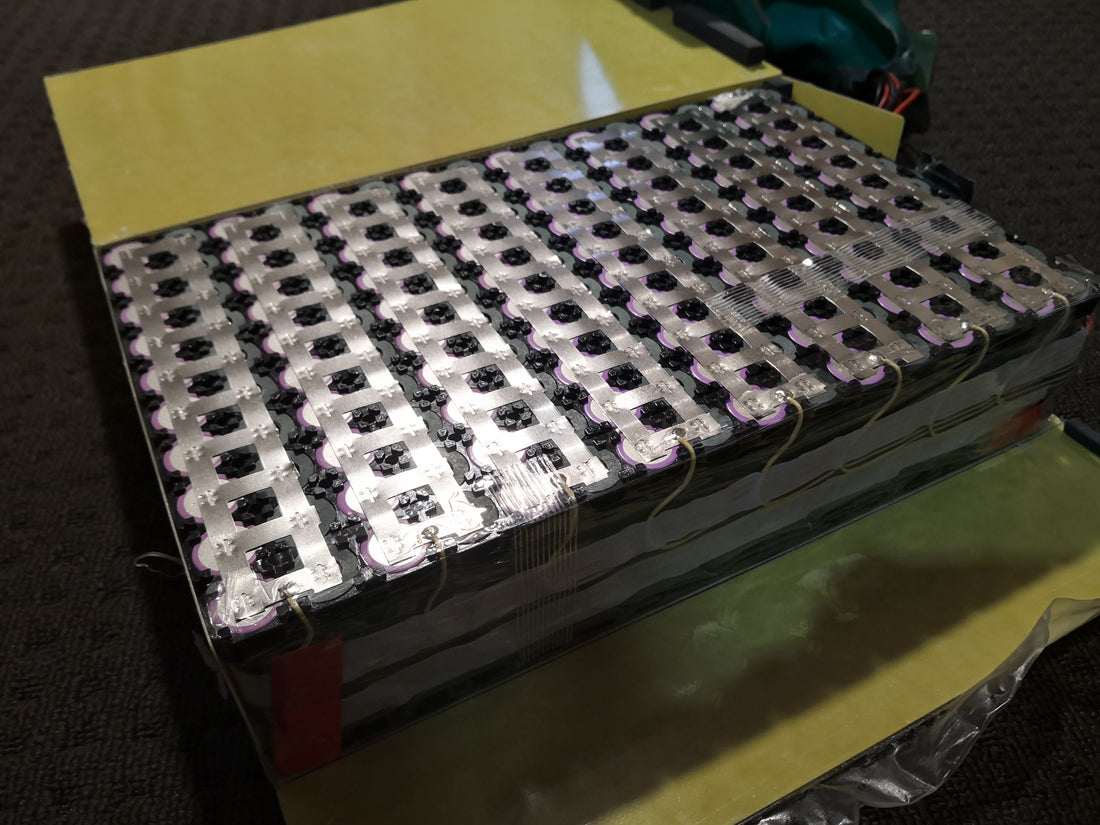

During battery creation, individual cells are meticulously selected, ensuring they are in similar condition and capable of sustaining equal voltages. Cells must be from the same brand and follow particular specifications. Connecting cells with varying internal resistance or differing voltages in parallel can lead to thermal runaway (fire).

The cells are then arranged in a planned layout, creating the final battery shape, with protective measures such as insulator washers and low-heat glue (in some cases) to secure cells in place. Insulator rings prevent short-circuits (see the green ring washer in Image 6 below), and some cells even have internal protection mechanisms against thermal runaway. A battery should be fitted with a Battery Management System (BMS) and balance wires, which are additional safety mechanisms. Some batteries are encased within plastic cell holders for extra protection from high impacts (see Image 10 below).

Subsequently, cells are banked, i.e., connected in parallel, and then these parallel "banks" are connected in series with thin nickel strips used for connection (copper may be used). Professional spot welding is crucial to prevent cell punctures. Poor-quality manufacturers may take shortcuts, compromising safety. Shortcuts may include using metal strips coated with nickel only, not fully nickel-plated, using strips that are too thin for the drawn current, soldering connections in lieu of spot welding, and not using insulating washers. At Electric Pedal Power, we trust reputable suppliers only for quality assurance.

More parallel-connected cells increase the amp-hour rating, correlating with higher discharge and charge current abilities. More cells in series result in higher overall battery voltage, providing more power and speed for an electric motor. However, a trade-off exists due to a limited number of cells available for a given battery size. For example, to achieve a target voltage of 36V, we need to link several 18650 cells in a series configuration. The nominal rating for lithium-ion battery cells is typically 3.6 or 3.7V. Therefore, to attain a nominal voltage of 36V, we must connect 10 cells in series. A 36V battery with, say, 20 18650 total cells, therefore, has 2 in each parallel bank. However, if our target voltage is 72V for the same number of 20 18650 cells, we're only left with 1 cell in each "bank."

Image 5: In it's purest form, three Li-ion cells connected in series for a higher voltage (magnets not recommended -demo only)

Image 6: An exemplary well-insulated e-bike battery.

Image 7: An example of a poorly built battery leading to internal shorting.

Image 8: The same poorly constructed battery example with inconsistencies, deformed nickel strips and lack of insulation.

Image 9: A small powertool battery illustrating cells connected in parallel and series.

Image 10: The use of a plastic cell holder as an additional safety precaution.

Image 11: A well-built battery with good spot welding and insulation.

Image 12: The same properly assembled battery with a BMS and clean wiring.

Image 13: Again the same neatly designed battery with extra thick external insulation and foam padding.

4. Not all cells are created equal

Recognising the specific brand and model of cells inside a battery is paramount. Datasheets for individual cells provide valuable information on capacity, discharge, and charge ratings. For example, the battery cell called 'Molicel P42a' is renowned for its high energy density, offering increased range and power for DIY e-bikes, albeit at a higher cost compared to other alternatives.

Thoroughly investigating and selecting cells based on their specifications ensures optimal performance and safety for e-bike and e-scooter batteries.